Hewland Engineering

Around 95 per cent of the parts are programmed through Edgecam, and almost all are complex, with tight tolerances of between five and ten microns.

Case Study Summary

Company name: Hewland Engineering

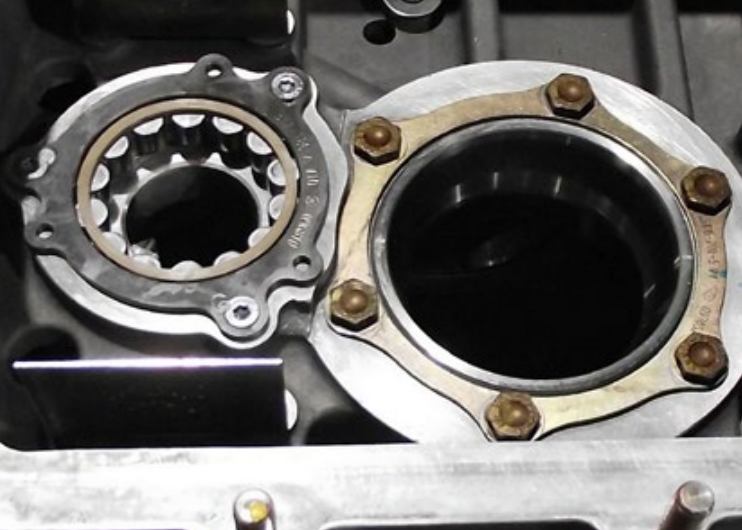

Business: Gearbox and transmission systems

Website: http://www.hewland.com

Benefits achieved:

- Astonishing results in reducing time and tooling costs

- Considerable savings on component cycle time

- Able to offer far more competitive prices to customers

- Moving from manually inputtinng values to having values automatically changed

EDGECAM halves Hewland fork cycle time, and slashes tooling costs

“It’s now used for all our face grooves, groove turning, and full rad inserts, which has reduced cycle times dramatically.”

- Dominic Prinsloo, Production Engineering Manager